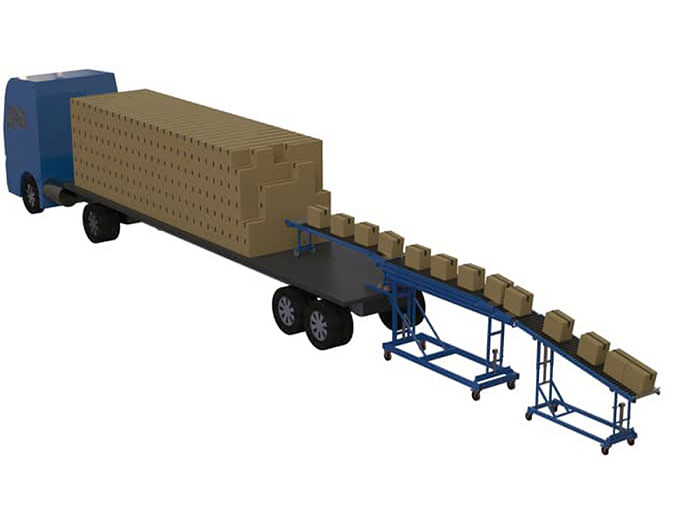

See below for examples of the type of Conveyor Systems we offer:

Our wide selection of powered and gravity conveyors to load/unload vehicles and containers. These robust units allow simple operation to load or unload your vehicles making a perfect solution for use with 20ft and 40ft containers or trailers.

We have both belt and roller conveyors, smaller belt conveyors are perfect for loading & unloading smaller vans, larger options of gravity roller or powered belt conveyors are brilliant for conveying further into large vans and lorries. Our ‘Telescopic Conveyors’ for fast unloading of container vehicles with a loading dock and ‘High Rise Telescopic Conveyors’ for fast unloading of container vehicles without a loading dock. We also offer powered belt and roller conveyors, fantastic at loading and unloading without the need of a dock leveller.

We offer a wide selection of powered horizontal belt conveyors manufactured to a very high specification. A wide range of sizes, drive configurations and finishes cater for most applications.

All types of belt finishes and belt materials are available, smooth belt and grip top belts for standard handling requirements, heavy duty conveyor belts, fire retardant and food quality belts. The comprehensive range includes various types of drive units individually designed for the purpose required. These include end drives, integral drum drives and variations of centre drives.

Robustness and quality are common across the range, with all support stands manufactured from heavy gauge hollow steel. For easy installation and levelling, all powered belt conveyors can incorporate adjustable supports.

There is a large range of gravity roller conveyors for almost any application or industry. Our gravity conveyors can offer a cost effective simple solution for most conveying requirements. Capable of handling products as small as 75mm long up to fully loaded pallets.

Many types of rollers and side frame materials are available, including aluminium and stainless steel, to suit general, hygienic or food grade applications. Our gravity conveyor is a formed steel side frame with spring loaded rollers, offering a smooth aesthetically pleasing side frame. For maximum versatility ‘speedtrack’ is available in modular straight sections, bends, spiral bends, gates and merges. All units can be linked to the gravity and powered ranges.

Highly mobile and extremely flexible, these conveyors can be moved, stretched out and positioned in minutes. Simply wheel it out and expand it straight or around bends to suit your needs.

When finished just close the unit up and store away. This flexible conveyor has lattice side frames which enable it to be stretched around corners or even tight bends with ease. These machines can be used on their own or to supplement existing installations in stores, warehouses or assembly lines.

Our flexible conveyors can be fitted with low inertia plastic or steel skate-wheels, plastic or steel rollers, mild steel and stainless steel bearings are available, allowing all types of goods to be accommodated. Standard Duty and Heavy Duty powered roller models available.

We offer various types of package and tote handling powered roller conveyor to suit many customers conveyor requirements.

Line-Shaft Powered Roller Accumulation Conveyor:

Lineshaft accumulation conveyor drives rollers via elasadrive bands from a drive spool, in turn these are driven by an under-slung drive shaft powered by an AC 240/415volt motor gearbox. The friction between the spool and the shaft drives the roller.

This type of roller conveyor offers accumulation properties once the line pressure exceeds the drive. Various modular ancillary accessories are available to assist in mechanically controlling the product.

24volt DC – “ZLP” Zero Line Pressure Powered Conveyor:

This type of powered roller conveyor has a positive drive. Slave rollers are driven by linked drive belts to form a drive zone. Each zone section is powered by a centrally mounted 24volt DC motor and represents a product a zone which is controlled via intelligent drive cards. These cards allow plug and play configurations and have preprogramed logic options. Purpose conveyor roller sensors are used to detect the product.

Belt Under Roller Zero Line Pressure “ZLP” Powered Roller Conveyor:

Belt-under roller drives precision gravity rollers by a belt running under the rollers. A pneumatically operated rack pushes the belt to the underside of the rollers to drive the product. As upstream accumulation of product is detected the rack releases turning the conveyor back into a gravity conveyor. This obviously has ideal zero-line pressure accumulation properties. Once the accumulated product up stream restarts a signal is sent to lift the pneumatic racks to drive the rollers once again.

A magnetic conveyor is a belt conveyor which uses magnetism to control the movement of items on the belt. The magnetic conveyor working principle is that items conveyed are made from ferrous or iron-containing metals so that these stick to the belt all the way along.

Strong magnets or electromagnets are fixed at intervals beneath the conductive belt to create a magnetic field. The belt is typically made from sheet metal, allowing it to be magnetised at all points, causing any magnetic materials to stick to the belt for the full length. This means that even if the belt is moving vertically, over an incline or decline, as long as the materials conveyed are made from steel and other ferrous metals will be fixed securely in place and carried safely to their destination.

A magnetic conveyor may be right for your business if:

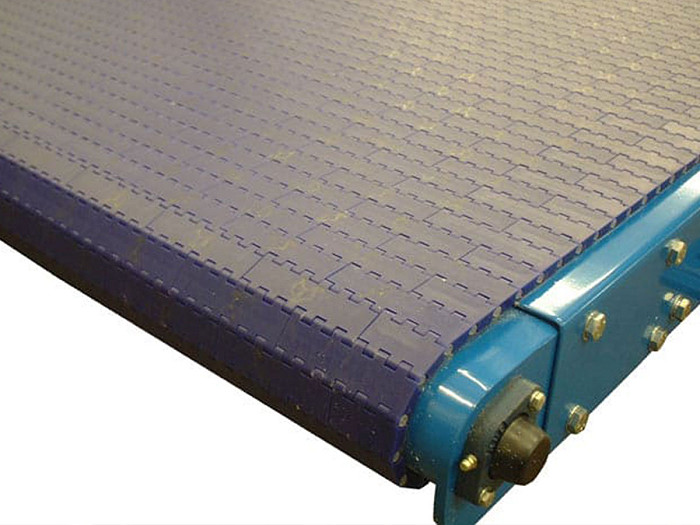

Used in many arduous environments from subzero conditions up to temperatures over 100 degrees Celsius. They are especially useful for heavy side loading or off-loading along its length. The direct sprocket drive ensures no tracking problems, whatever the belt width or length.

It also eliminates any belt slippage and because it allows the belt to run loose dramatically reduces load on the drive shaft bearings.

This in turn reduces power requirements. With the all-round low friction properties of these conveyors the outstanding feature must be long life expectancy with minimal maintenance.

Belts are available in many different profiles and materials to suit almost every application.

Positive direct sprocket drive ensures no tracking problems.

Robust heavy duty belt types resistant to cuts and hot products.

Available in many belt configurations, flat-top, perforated, slotted, flighted and grip top.

Damaged belts can easily have individual slats replaced.

These machines can be constructed with either mild steel or stainless steel framework. Mild steel is perfect for most post and parcel applications & stainless steel is ideally suited to the food industry where washdown situations are a regular requirement.

These belts are even available with rollers in to achieve product accumulation.

Standard material types: Polypropylene (PP) for use in many general applications. Polyethylene (PE), another lightweight thermoplastic, is characterized by superior fatigue resistance, high impact strength, and flexibility. Acetal (PA) thermoplastics are considerably stronger than PP and PE. Acetal features a good balance of mechanical, thermal, and chemical properties and a low coefficient of friction.

Contact our team today to get a free quote and find out how we can help.